Green Construction Solutions: Best Materials, Benefits & Buying Guide

The Rise of Green Construction: Why It Matters

Green construction (or sustainable construction) refers to design, building, operation, and demolition practices that minimize environmental impact, reduce resource consumption, and enhance occupant health. As concerns over climate change, urban pollution, and resource depletion intensify, green construction has moved from niche to mainstream. For builders, developers, and homeowners, adopting green construction methods can translate into lower operating costs, higher asset value, improved comfort, and compliance with increasingly strict building codes or incentives.

Key Principles Underpinning Green Construction

Before diving into specific materials, it’s helpful to understand the guiding principles behind sustainable construction choices:

-

Minimize embodied carbon – prioritize materials and processes with lower upstream emissions.

-

Resource efficiency & waste reduction – use recycled, reclaimed, or waste‑derived materials; design for modularity and deconstruction.

-

Energy performance – design building envelopes and systems that minimize heating/cooling loads.

-

Health & indoor environmental quality – avoid materials that off‑gas volatile compounds; use breathable, non-toxic components.

-

Durability & adaptability – longer-lasting materials and systems reduce replacement cycles and future waste.

-

Local materials & supply chains – sourcing locally cuts transport emissions and supports regional economies.

With these in mind, selecting green construction materials becomes a matter of matching performance, cost, availability, and climate suitability.

Top Green Construction Materials & Their Benefits

Below are several high-impact sustainable materials used in green construction. Each section discusses how the material works, benefits, problems it solves, and real-world considerations.

Cross‑Laminated Timber (CLT) & Mass Timber

Cross‑Laminated Timber is created by gluing together layers of dimensioned lumber so that adjacent layers cross at right angles. This structural panel can be used for floors, walls, and roofs.

Because CLT sequesters carbon (wood stores CO₂ absorbed during tree growth), using mass timber reduces the net carbon footprint compared to concrete or steel structural systems. Its prefabricated nature accelerates construction, reduces waste, and improves site safety.

Use case & problem solved: In multi-story residential or commercial buildings, CLT can replace steel or concrete frames, offering a lighter structure with lower embodied carbon. Because it is wood-based, it also provides better inherent insulation. In regions with strong forestry capacity, it supports local timber industries and reduces import dependency.

Considerations: Moisture protection, fire performance, and connection design are critical. Mass timber elements must be detailed to avoid decay, and fire design must rely on char modeling.

Green / Low-Carbon / Geopolymer Concrete

One of the most promising directions is reducing the reliance on ordinary Portland cement. Geopolymer or low-carbon concrete replaces a portion of cement with industrial by‑products such as fly ash, ground granulated blast furnace slag (GGBS), or uses alternative binders. Some innovations even capture CO₂ during curing.

This type of concrete can reduce emissions by up to 70–80% relative to traditional mixes. It maintains structural performance for slabs, beams, foundations, and precast elements.

Use case & problem solved: For a new development seeking green certification, specifying green concrete for slabs and columns lowers the embodied carbon of major structural elements. It solves one of the largest emission contributors in conventional construction (cement) and supports durability and lifespan.

Considerations: Regional availability of supplementary cementitious materials (fly ash, slag) matters. Some jurisdictions may require performance validation, and builders must ensure compatibility with workability, curing, and long-term durability.

Recycled Steel & Metal Components

Steel is extensively recycled worldwide. Using recycled or certified low-carbon steel for beams, reinforcing bars, roof structures, or structural frames helps reduce demand for virgin production.

Recycled steel maintains the strength, durability, and recyclability of new steel. In green construction, it plays a role when spanning long distances or when modular or prefabricated metal framing systems are desired.

Use case & problem solved: In projects requiring open floor plans or large spans, steel beams are often unavoidable. Using recycled steel or specifying steel with high recycled content retains functionality while improving sustainability.

Considerations: Although steel is recyclable, you must address thermal bridging in metal framing (insulation breaks), corrosion protection in humid environments, and interface with other materials.

Hempcrete & Bio‑Composites

Hempcrete (a mix of hemp hurd and lime binder) is a bio‑composite used as an infill or insulation layer—not as a structural load-bearing element.

It has several compelling benefits: it absorbs CO₂ during curing (carbon negative), offers excellent thermal and acoustic insulation, is breathable (moisture-regulating), and is mold- and pest-resistant.

Use case & problem solved: In energy-efficient homes or retrofit projects, hempcrete can replace conventional insulation (e.g. fiberglass) in wall cavities or even act as a wall infill behind a structural frame. It addresses overheating, condensation, and insulation deficits.

Considerations: Since hempcrete is not structural, you must combine it with a structural frame. Availability and cost can be limiting in many regions. Detailing is critical to avoid moisture ingress or improper curing.

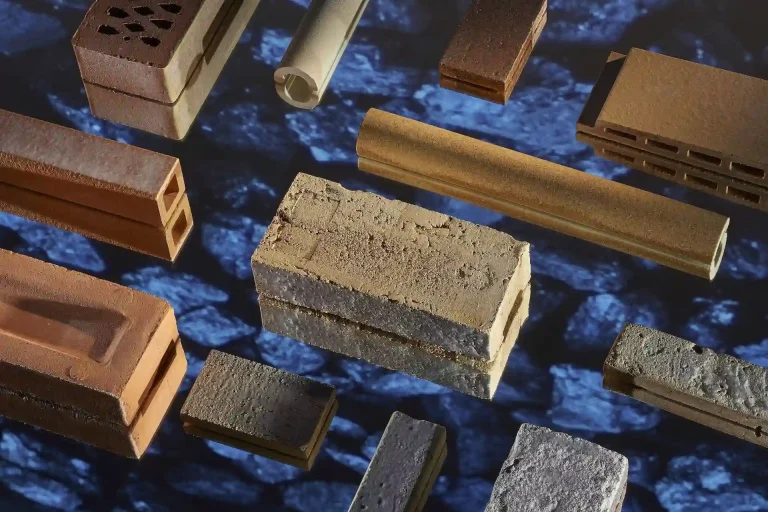

Eco-Blocks & Photocatalytic Bricks

Eco-Blocks are bricks made from recycled glass, waste aggregate, fly ash, and sometimes surface photocatalysts (e.g. TiO₂). Their key feature is that the surface layer helps break down air pollutants (e.g. nitrogen oxides) when exposed to sunlight.

These bricks reduce waste by using demolition by-products and contribute to air cleaning in urban settings.

Use case & problem solved: Use Eco-Blocks for paving, facade cladding, or even non-load-bearing brick walls in urban construction. They help reduce urban air pollution while repurposing waste.

Considerations: Their mechanical strength must meet design specifications. Photocatalytic performance may degrade over time; their cost premium must be justified relative to conventional bricks.

Green Certified & Ultra‑Low Emission Panels (Greengridz)

Greengridz is a composite wood product designed for sustainable construction. It is TSCA Title VI / CARB2 compliant (low formaldehyde emissions), and meets Nordic Swan ecolabel.

Because they emphasize certification and low emissions, these panels support healthy indoor environments and green building rating systems (e.g. LEED, BREEAM).

Use case & problem solved: Use Greengridz panels in wall sheathing, interior partitions, cladding, or furniture components where indoor air quality and low-VOC performance matter. They help reduce off-gassing and contribute to healthier living spaces.

Considerations: Panels must still be integrated properly with vapor barriers or breathable membranes depending on climate. Design for durability and compatibility with adjacent materials.

Real Product Examples You Can Inspect or Purchase

Here are some commercial product examples (or material types) you can explore. Each begins with an image reference and deeper insight.

APLUS Water‑Resistant Green Gypsum Board

This is a gypsum board with enhanced moisture resistance, often used for interiors in damp areas (bathrooms, wet kitchens). Because it’s part of interior finishing, choosing a “green” gypsum board means lower emissions, reduced maintenance, and better durability in humid climates.

Benefits & technical detail: Unlike standard gypsum boards, this moisture-enhanced board resists mold, delamination, and sagging in humid zones. Its lower formaldehyde and low-VOC materials help maintain healthier indoor air quality.

Use case & problem solved: In tropical climates or rainy regions, interior finishes are challenged by humidity, mold, and dampness. This board prevents moisture damage and keeps interior surfaces stable over time.

How to buy / where: APLUS Water‑Resistant Green Gypsum Board

Recycled Non‑Slip Sheet (Recycled Material)

This sheet is made from recycled polymers and designed for slip resistance (e.g. stair treads, wet areas, outdoor decks). It is an example of a finishing product that embodies reuse and sustainability.

Benefits & technical detail: The sheet reduces waste by using recycled inputs. It provides safe walking surfaces (anti-slip) and is durable in exposure to moisture. Because it is polymeric, it resists rot, termites, and decay.

Use case & problem solved: Outdoor stair treads or decks often need durable, skid-resistant surfacing. Traditional wood or untreated materials rot or degrade; this recycled sheet provides a sustainable alternative.

How to buy / where: Recycled Non‑Slip Sheet

Rust‑Oleum Industrial Choice M1400 Water‑Based Marking Paint

Although not structural, this product exemplifies choosing low-VOC, water-based finishes even in site or industrial settings. It shows that green construction includes coatings and auxiliary materials, not just structure.

Benefits & technical detail: Water-based marking paint eliminates strong solvents, reducing VOC emissions. It’s safer for workers and environments, and meets stricter emission standards.

Use case & problem solved: Site demarcation, safety lines, or markings for floor plans typically use high-emission paints. Using lower-VOC paint reduces indoor/outdoor air pollution during and after construction.

How to buy / where: Rust‑Oleum Industrial Choice

Green Geomat for Construction & Landscape

This geomat (geosynthetic mat) is used in landscaping, erosion control, retaining walls, or soil stabilization. Although not a primary structural component, it participates in sustainable site design.

Benefits & technical detail: The geomat aids in slope stabilization, reduces soil erosion, promotes vegetative support, and may be made from recycled or durable polymers to last while reducing maintenance.

Use case & problem solved: On sloped sites or landscaped zones, soil erosion is a construction challenge. A geomat provides a vegetative substrate, reduces runoff and sediment mobilization, and supports green site integration.

How to buy / where: Green Geomat

Ashman Plastic Mesh Barrier Net

This mesh net (plastic-based) is often used for safety barriers, temporary fences, or site control. While less structural, it demonstrates that even auxiliary items in a construction site can be chosen for durability, reuse, or recycled content.

Benefits & technical detail: The mesh is durable, reusable over multiple phases, and helps reduce single-use barriers. If made with recycled plastic, its life cycle impact is lower.

Use case & problem solved: Instead of cheap, single-use barrier tapes or nets, using reusable barrier mesh reduces waste over the construction schedule.

How to buy / where: Ashman Plastic Mesh Barrier Net

Detailed Benefits: What Green Construction Delivers

Reduced Carbon & Embodied Energy

Green materials like CLT, low-carbon concrete, hempcrete, or Eco-Blocks help cut down the upstream emissions from raw material extraction and processing. By avoiding high-carbon inputs (e.g. pure Portland cement or virgin steel) and opting for recycled or bio-based materials, the total embodied carbon of the building drops significantly.

Better Energy Performance & Lower Operating Costs

Green construction often pairs efficient materials with high-performance envelopes. CLT, hempcrete, or eco-insulations reduce heat transfer; integrated passive solar strategies and shading systems also minimize the need for mechanical heating or cooling. Over the building’s lifetime, energy savings can offset initial costs.

Healthier Indoor Environments

Using low-VOC materials, certified wood products, breathable walls (e.g. hempcrete), and avoiding toxic finishes ensures better indoor air quality. In tropical climates, managing humidity and mold risk is essential to occupant health; green materials help regulate moisture and resist biological growth.

Longevity, Durability & Lower Maintenance

Durable, well-specified materials (modified wood, recycled steel, green concrete) require less frequent repair or replacement. This durability reduces lifecycle cost, material waste, and disruption. Materials like CLT and modified wood can also age gracefully if maintained correctly.

Regulatory, Certification & Market Advantage

Many jurisdictions and building rating systems (LEED, BREEAM, Green Building Councils) favor or require sustainable materials. Buildings labelled “green” often attract premium rent or resale value and meet investor and occupant expectations.

Site & Resource Efficiency

Green construction often emphasizes modularity, prefabrication, waste reduction, lean logistics, and local materials. These reduce waste on-site, lower transportation emissions, and speed construction.

Implementation & Use Cases: How to Apply Green Construction

Hybrid System Design

Most green buildings use hybrid systems: a structural core (CLT, steel, or reinforced concrete) combined with green or bio-based infill, insulation, and finishing materials. For example, a CLT shell coupled with hempcrete or Eco-Blocks, and finished with low-VOC boards or certified wood panels, yields a holistic green structure.

Moisture & Climate Adaptation

In tropical or humid climates, design details are essential: overhangs, drainage, vapor-permeable membranes, breathable finishes, and moisture barriers must align with material properties.

Testing & Certification

Always demand technical data, test reports (compressive strength, fire rating, moisture resistance), and third-party certification. This ensures the materials meet structural, health, and building code requirements.

Local Sourcing & Adaptation

Select materials available or producible locally to reduce transport emissions. For instance, if your region has abundant timber, engineered wood products may be more viable than imported composites.

How to Buy & Where to Source

Steps to Procuring Green Construction Materials

-

Define required performance metrics (structural strength, insulation R-values, fire resistance, moisture resistance).

-

Search specialized green material suppliers in your country or region (e.g. timber mills, sustainable concrete plants, biomass composites).

-

Request samples and data sheets to verify performance and compatibility.

-

Consult architects or engineers familiar with sustainable systems for integration and validation.

-

Check project procurement channels – many green materials are now listed in sustainable building catalogs or certification-based directories.

-

Plan logistics & installation sequencing – some materials (mass timber panels, precast green concrete) require more careful delivery and handling.

Closing Thoughts

Green construction is not a mere fad it is the necessary evolution of building practices in response to climate, resource, and societal pressures. By selecting materials like CLT, low-carbon concrete, recycled steel, hempcrete, Eco-Blocks, and certified panels like Greengridz, builders can significantly lower environmental impact while improving energy efficiency, occupant health, and long-term value.

When you choose “green construction materials” as your transactional keyword, you’re reaching people who are ready to take action those deciding how, where, and what to build with. This article helps connect that intent with concrete options, use cases, and buying pathways.

Frequently Asked Questions

Q1: Are green construction materials significantly more expensive than conventional ones?

A: Often, the upfront cost is higher due to smaller production scale, specialty processing, or transport. However, lifecycle cost savings energy, maintenance, longer life often make green materials economically competitive, especially over 10–20 years.

Q2: Will my local building code accept these innovative materials (e.g. hempcrete, cross-laminated timber)?

A: Many jurisdictions are gradually adapting to novel materials. Always check local codes, demand test reports or certifications, and engage structural/fire engineers. Sometimes performance-based approval is allowed.

Q3: Is green construction suitable for all climates (humid tropics, cold zones, seismic regions)?

A: Yes with proper design adaptation. Materials must be selected to suit moisture, thermal, seismic, and climate loads. For tropical climates, breathable walls, vapor membranes, and moisture detailing are especially important. If you like, I can help tailor green construction strategies for your specific climate or region.