Buy Sustainable Building Products for Green Construction: Ultimate Guide

Understanding Sustainable Green Building

Sustainable green building refers to designing, constructing, and operating buildings in ways that minimize resource use, reduce environmental impact, and improve occupant health and comfort. Green buildings integrate energy efficiency, water conservation, low-impact materials, indoor environmental quality, and smart systems.

These buildings aim to reduce operating costs, lower carbon emissions, and often qualify for green certification programs (LEED, BREEAM, etc.). According to ecoChain, key features of green buildings include sustainable materials, energy‐efficient systems, water conservation, and indoor air quality control.

One of the central pillars is using materials that have lower embodied carbon, durability, recyclability, or regenerative characteristics. When you plan to buy sustainable building products, choosing the right materials is critical not only for performance, but for the long-term environmental footprint of your building.

Key Criteria for Choosing Green Building Materials

Before diving into particular materials and product examples, it’s important to know the selection criteria that separate truly sustainable building products from green-washing claims.

Lifecycle and Embodied Carbon

A material’s sustainability depends heavily on its “cradle-to-grave” or lifecycle impact. This includes extraction, manufacturing, transport, installation, maintenance, and eventual disposal or recycling. Materials that emit high CO₂ in their production or cannot be reused/recycled are less desirable.

Durability, Maintenance, and Longevity

Even a low-carbon material is not truly sustainable if it must be replaced often. Materials that resist wear, weathering, pests, and degradation reduce waste and life-cycle cost.

Recyclability, Renewability, and Circularity

Materials that can be reclaimed, recycled, or restored back into the ecosystem are more sustainable. Renewable materials (e.g. plant-based, wood, cork) or those from waste streams (recycled steel, plastic, glass) help close the material loop.

Non-Toxic & Indoor Health

Green building materials should not emit volatile organic compounds (VOCs), formaldehyde, or toxic additives. They should promote healthy indoor air, prevent mold or off-gassing, and be compatible with human comfort.

Local Sourcing & Reduced Transportation

Sourcing materials locally reduces transport energy and emissions. The closer a sustainable product comes to your build site (while meeting quality standards), the better its environmental performance.

Exemplary Sustainable Building Products

Below are five real product examples that align with green building principles. Each is described in detail: features, benefits, use cases, and how to buy. These serve as models you can adapt or replace with local equivalents.

1. Eco Formaldehyde Ecological Plywood Sheet

Product Example: Eco Formaldehyde Ecological Plywood Sheet

This is a plywood manufactured to minimize or eliminate formaldehyde emissions. It is marketed as ecological plywood, suitable for interior sheathing, furniture, cabinetry, or veneer surfaces.

Features & Performance:

-

Low- or no-added-formaldehyde binder to reduce off-gassing

-

Multi-layer veneer core for dimensional stability

-

Standard sheet size (e.g. 4 × 8 ft) and various thicknesses

-

Ability to accept finishes, laminates, or direct paint

Benefits in green building:

Using low-VOC plywood improves indoor air quality and occupant health. The durability of plywood ensures it doesn’t delaminate or degrade prematurely, reducing maintenance. It is a drop-in replacement for conventional plywood with much less toxic impact.

Use Cases & Problems Solved:

-

Interior wall sheathing where moisture levels are controlled

-

Cabinets, shelving, built-in furniture where occupants spend close proximity

-

Subflooring or structural bracing in low-moisture environments

In conventional plywood, formaldehyde emissions are a serious problem; this product solves that while maintaining utility.

How to Buy & Where to Buy:

You can search for “low-formaldehyde ecological plywood” or “E0/E1 ecological plywood” in building material suppliers, architectural wood product stores, or importers. Buy Low-Formaldehyde Plywood

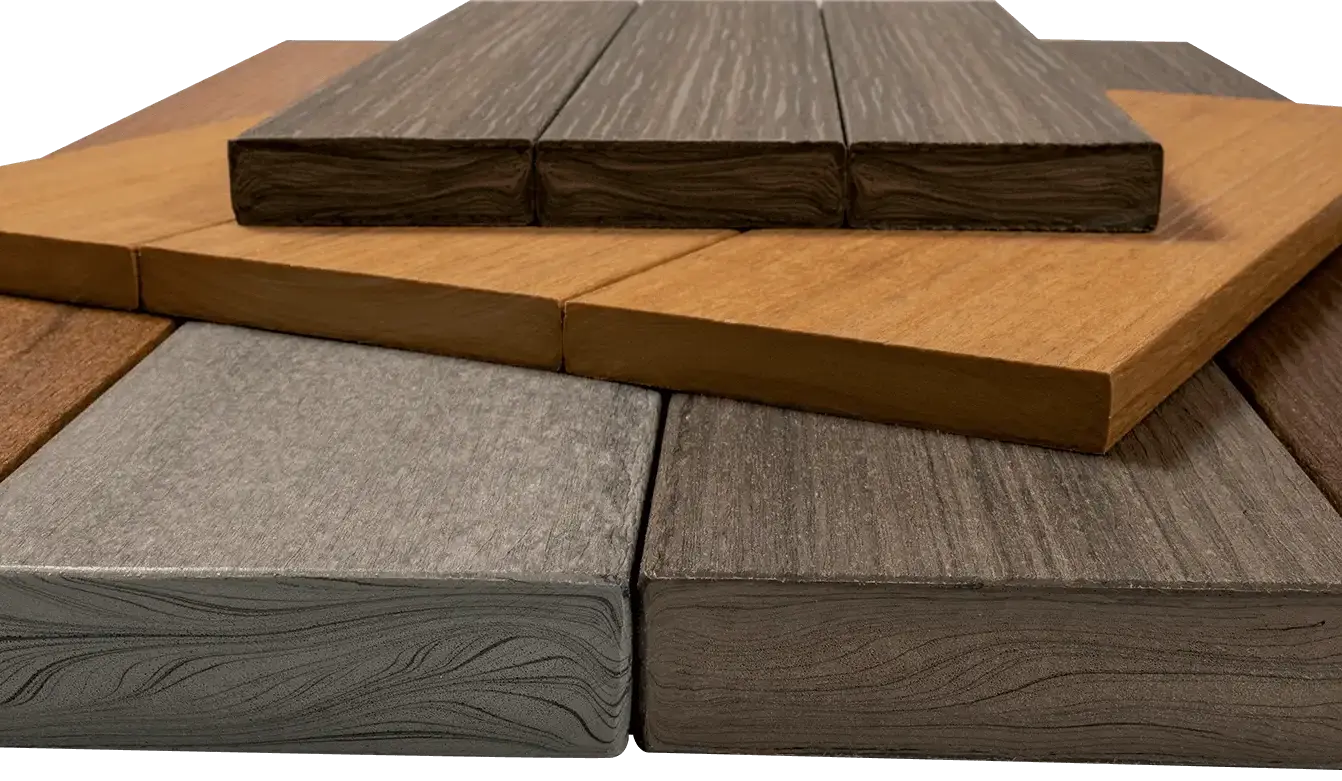

2. Tangent Poly Lumber (Recycled Plastic Lumber)

Product Example: Tangent Poly Lumber

This is a structural-grade lumber made from recycled plastic. It is intended to replace wood lumber in outdoor decking, railing, structural framing, or landscaping components.

Features & Performance:

-

High strength and stiffness compared to typical plastic boards

-

Resistant to rot, termites, moisture, and UV if properly formulated

-

Low maintenance: no painting or sealing needed

-

Often made from post-consumer plastic waste (HDPE, PP, etc.)

Benefits in green building:

Poly lumber diverts plastic waste from landfills and reduces demand for virgin timber. It performs well in harsh outdoor environments, eliminating the maintenance burden of wood. It also resists warping, cracking, and splitting.

Use Cases & Problems Solved:

-

Outdoor decks, pergolas, walkways, boardwalks

-

Structural beams in humid or marine environments

-

Fencing, railing, and guardrails

-

Situations where wood would rot or require frequent repainting

This product addresses the problems of wood decay, termite damage, and plastic waste.

How to Buy & Where to Buy:

Search “poly lumber supplier” or “recycled plastic structural lumber.” Many e-commerce platforms or specialty building material suppliers offer dimensional lengths. Buy Tangent Poly Lumber

3. Mineral Poplar Reclaimed Wood

Product Example: Mineral Poplar Reclaimed Wood

This is reclaimed poplar wood with a mineral wash finish, used for flooring, wall cladding, siding, or decorative beams.

Features & Performance:

-

Reclaimed timber harvested from decommissioned or salvaged structures

-

Kiln-dried, clean, and stable

-

Mineral-stain or whitewash finish that accentuates grain

-

Varied board widths and lengths

Benefits in green building:

Reclaimed wood reduces deforestation and keeps existing wood in use. It carries embodied carbon from its first life. Its aged character adds aesthetic warmth and authenticity. When properly processed, its structural integrity is maintained.

Use Cases & Problems Solved:

-

Hardwood flooring with character and low new wood demand

-

Accent walls or interior cladding

-

Exposed ceiling beams to create warm, natural ambiance

-

Furniture or cabinetry to match sustainable wood finishes

This product solves the environmental cost of new timber and gives buildings character.

How to Buy & Where to Buy:

Look for reclaimed wood suppliers or salvage yards offering dimensioned boards. Many specialize in domestic species and deliver milled wood. Buy Reclaimed Poplar Wood

4. Eco-friendly Corrugated Roofing Sheet

Product Example: Eco Friendly Corrugated Roofing Sheet

Corrugated metal or composite roofing designed to be durable, recyclable, and made from low-impact materials.

Features & Performance:

-

Galvanized or coated metal with corrosion resistance

-

Possibly containing recycled metal content

-

Lightweight design, compatible with many roof systems

-

UV-reflective finish to reduce heat gain

Benefits in green building:

This roofing sheet reduces heat absorption, thereby lowering cooling loads. Metals are easy to recycle at end-of-life. Durable coatings extend lifespan and reduce maintenance. The lightweight nature also reduces structural demands.

Use Cases & Problems Solved:

-

Roof covering in tropical climates where solar reflectance matters

-

Shed roofs, carports, industrial buildings, lightweight housing

-

Retrofit over existing structure to avoid ripping off old roof

-

Situations where long lifespan and low maintenance are key

This product solves problems of overheating roofs, frequent roofing replacement, and waste.

How to Buy & Where to Buy:

Search “eco corrugated roofing sheet supplier” or “recycled metal roofing.” Many roofing material distributors and metal suppliers stock these. Buy Eco Corrugated Roofing

5. GRC Board (Glassfiber Reinforced Cement Board)

Product Example: GRC Board Timberplank 8 mm

GRC board is Fiber-reinforced cement board (glass-fiber reinforced) used for cladding, soffits, facades, and decorative paneling.

Features & Performance:

-

High resistance to moisture, fire, and pests

-

Stable, dimensionally accurate, and flexible

-

Accepts paints, textures, and facades

-

Long lifespan with low finishing maintenance

Benefits in green building:

It replaces wood or synthetic panels with a more durable, non-toxic, low-maintenance alternative. Because it resists mold, pests, and humidity, it supports indoor health and durability. It is also less wasteful over time.

Use Cases & Problems Solved:

-

Exterior cladding or architectural facades

-

Soffits, fascia, exterior ceilings

-

Decorative wall panels in humid environments

-

Situations where a stable, weatherproof panel is needed

This product addresses the issue of wood rot, termite damage, and frequent repainting.

How to Buy & Where to Buy:

GRC boards are available through cement board, facade, or architectural material suppliers. You may request custom panel sizes and finishing options. Buy GRC Board

Benefits of Using Sustainable Building Products

Using sustainable building products yields deep benefits when aligned with smart building design and technology.

Lower Embodied Carbon & Climate Impact

By substituting conventional materials with recycled, renewable, or low-carbon alternatives, the total carbon footprint of your building is significantly reduced. Materials like reclaimed wood, recycled plastic lumber, low-VOC plywood, and durable roofing sheets all contribute to lower embodied emissions.

Operating Efficiency & Energy Savings

Green building products aid thermal performance, reduce heat gain or loss, and enhance insulation. Corrugated reflective roofing, stable wall panels, and durable cladding all help reduce cooling or heating loads. Over time, these energy savings often exceed initial cost premiums.

Better Indoor Environmental Quality

Products like low-VOC plywood and mold-resistant GRC boards help maintain healthier air inside. Reducing sources of off-gassing, moisture problems, and toxic emissions leads to more comfortable, safer living or working conditions.

Durability, Resilience & Reduced Maintenance

Sustainable products tend to last longer, resist pests, resist weather, and need less upkeep. Fewer replacements means less waste, lower life-cycle cost, and better return on investment.

Marketing & Certification Value

Green buildings built with verifiable sustainable materials often receive higher valuations, faster sales or leasing, and qualify for LEED, BREEAM, or other green certification credits. The transparency of material sourcing and performance strengthens stakeholder trust.

Integrating Technology & Systems

Sustainable building is not just about materials integrating smart systems, renewable energy, and monitoring enhances performance.

Smart Monitoring & Controls

Sensors and IoT systems can monitor temperature, humidity, CO₂, and energy consumption. Adjusting ventilation, hydronic systems, lighting, and shading in real time improves efficiency. According to research on IoT frameworks for buildings, smart control can deliver substantial energy savings by dynamically matching demand.

Advanced Insulation & Composite Materials

New research into materials like bacterial-cellulose-based aerogels shows potential ultra-thin, high-performance insulation films that reduce heat flow significantly. Such innovations may soon complement traditional insulation systems, improving thermal efficiency with lower thickness.

Biomaterial & Living Systems

Emerging fields explore mycelium-based structural elements, modular algae facades (which capture CO₂), and 3D-printed earth homes such as the Tecla house built entirely from local clay. These concepts push the envelope of regenerative and adaptive construction.

A recent study also describes modular photobioreactor façade systems infused with algae, converting building facades into living carbon-capturing systems.

Such systems may still be niche today, but as they mature they can complement the sustainable building product portfolio.

Use Cases and Real-World Examples

Earthship Brighton (Autonomous Sustainable Home)

Earthship Brighton is an example of a self-sustainable building built from repurposed materials: car tires, bottles, cans, rammed-earth walls, rainwater harvesting, passive solar design, and renewable power systems.

It exemplifies how integrating recycled and low-impact materials with systems can produce autonomous, low-energy homes.

Tecla 3D-Printed Clay House

Built from local clay and earth via robotic 3D printing, Tecla house avoids conventional concrete and uses local materials, drastically cutting transport and material waste.

This demonstrates how sustainable products and methods can reduce embodied carbon on a dramatic scale.

BrightBuilt Barn (Net-Zero Demonstration Home)

BrightBuilt Barn, a LEED Platinum and net-zero home in Maine, uses solar panels, superinsulation, passive design, efficient systems and sustainable materials.

It demonstrates how sustainable building products combine with design and systems to achieve net-zero operation.

How to Buy Sustainable Building Products

When ready to buy sustainable building products, follow these steps:

-

Define performance parameters (strength, U-value, moisture behavior, fire rating) before selecting.

-

Vet supplier credibility: check certificates like EPDs, product test reports, green credentials.

-

Order samples or small batches to test finishes, handling, compatibility on your project.

-

Compare delivery / shipping costs, which often dominate in heavy materials.

-

Engage with manufacturers for custom sizing, finishes, or certifications.

-

Educate contractors on installation best practices (e.g. detailing for moisture, ventilation).

-

Document material sourcing to support certification or sales narratives.

Frequently Asked Questions

Q1: Are sustainable building products always more expensive?

Not necessarily. While some premium products carry higher upfront cost, many sustainable products competitively cost with conventional alternatives when factoring lifecycle savings in energy, maintenance, and durability.

Q2: Can sustainable products meet structural and safety standards?

Yes. Many sustainable materials (e.g. poly lumber, GRC boards, ecological plywood) meet or exceed building codes. Always check with structural engineers, building authorities, and supplier certifications.

Q3: How do I know a product is truly sustainable and not greenwashing?

Look for third‐party verification: EPDs (Environmental Product Declarations), ISO 14001, FSC certification (for wood), recycled content statements, performance test data, and supplier transparency. Ask for documentation and demand accountability.