Buy Sustainable Building Materials: Best Eco-Friendly Options to Build a Green Home

Core Principles of Sustainable Building Materials

To build a truly green home, choosing the right materials matters more than style. When you buy sustainable building materials, you commit to lower environmental impact, better energy performance, healthier indoor air, and long-term durability. A material earns sustainability by meeting multiple criteria: low embodied carbon, renewability or recyclability, local sourcing, non-toxicity, and strong performance over time.

Embodied carbon the emissions released during material extraction, processing, and transport can account for up to 10–20 % (or more) of a building’s total lifetime emissions. Choosing materials that absorb carbon (or have negative net emissions) further pushes the building toward carbon neutrality.

In what follows, we’ll examine key sustainable building materials, show real product examples, explain their benefits in detail, describe use cases and problem-solving roles, and guide you on how and where to buy them.

Bamboo

Material & Performance Profile

Bamboo is a fast-growing grass (not a tree) that reaches maturity in 3–5 years. Because of its rapid growth cycle, it can regenerate without replanting, making it a highly renewable resource. Engineered bamboo (laminated or strand-woven) converts raw poles into stable beams, panels, flooring, and structural elements.

Mechanically, bamboo provides high tensile strength (comparable to mild steel by weight) and decent compressive properties. When treated correctly (via borate, heat, or natural preservatives), it resists pests, fungi, and moisture.

Benefits & Advantages

-

Carbon sequestration: Bamboo sequesters CO₂ during growth, helping offset emissions.

-

Lightweight yet strong: Its strength-to-weight ratio makes it ideal for roofs, frames, and modular structures.

-

Thermal comfort: Bamboo provides decent insulation and helps moderate interior temperature swings.

-

Aesthetics & versatility: The fine grain and natural look suit both interior and exterior applications.

-

Reduced transportation impact: In many tropical regions (e.g. Southeast Asia), bamboo grows locally, lowering transport emissions.

Real-World Product Example

Product: MOSO® Bamboo Beams

These are pre-treated laminated bamboo beams offered in various cross sections and lengths, intended for structural and aesthetic use. They come with moisture- and pest-resistant finishes, FSC certification, and performance documentation.

Use Cases & Problem-Solving

-

Structural framing in lightweight or modular homes

-

Roof rafters, purlins, or secondary supports

-

Exterior sun-shading louvres, pergolas, or screens

-

Interior partition walls, ceilings, or finishes

Bamboo addresses problems such as deforestation (by offering a renewable alternative to hardwood), heavy structural weight (by being lightweight), and embodied carbon (by offsetting some emissions via sequestration).

How to Buy & Where to Buy

To buy sustainable building materials like bamboo beams, you should approach specialized distributors or manufacturers, especially in regions with bamboo cultivation (e.g. Indonesia, China, Vietnam). Use search terms like “laminated bamboo structural beam supplier” or “engineered bamboo building materials.” Ask for FSC certification and full product data. Some suppliers provide online ordering.

Buy Bamboo Beams

Hempcrete

Composition & Technical Properties

Hempcrete is a bio-composite made from hemp hurds (the woody core of hemp stalks) mixed with lime-based binders (such as hydrated lime, hydraulic lime, or pozzolanic additives) and water. Over time, the binder carbonates (absorbs CO₂), making hempcrete partly a carbon sink.

However, hempcrete lacks high compressive strength; thus it is typically used as a non-load-bearing infill or insulation wall, within a supporting frame of timber or steel.

Thermally, hempcrete offers good insulation (R-values depending on density) and excellent thermal mass and vapor permeability meaning it can regulate humidity and reduce condensation.

Benefits & Detailed Advantages

-

Carbon-negative potential: As it cures, hempcrete absorbs CO₂ from the air.

-

Humidity regulation: Its vapor permeability helps balance indoor moisture, reducing mold risk.

-

Acoustic insulation: It dampens sound, ideal for noise control in housing near busy roads.

-

Fire resistance: It is non-flammable, adding safety in constructions.

-

Natural, non-toxic: No synthetic chemicals or VOCs, making it healthy for occupants.

Real-World Product Example

Product: IsoHemp Hempcrete Blocks

These blocks are dimensioned (e.g. 600 × 300 × 200 mm) and designed for infill walls. They provide known density, thermal conductivity, and handling guidelines. Manufacturers supply technical datasheets and installation instructions.

Use Cases & Problem-Solving

-

Filling wall cavities in timber, steel, or concrete frames

-

Internal partition walls for insulation and acoustics

-

Retrofit insulation behind existing walls

-

Passive thermal envelopes in warm or cold-climate homes

Hempcrete mitigates overheating, moisture buildup, and energy loss, while contributing to carbon reduction. It solves the issue of conventional insulation materials that trap moisture or emit chemicals.

How to Buy & Where to Buy

To acquire hempcrete blocks or loose-fill hempcrete, contact low-carbon building material suppliers or green construction firms in Europe or North America. Request CO₂ absorption data and performance specs. Online vendors often allow sample ordering.

Buy Hempcrete Blocks

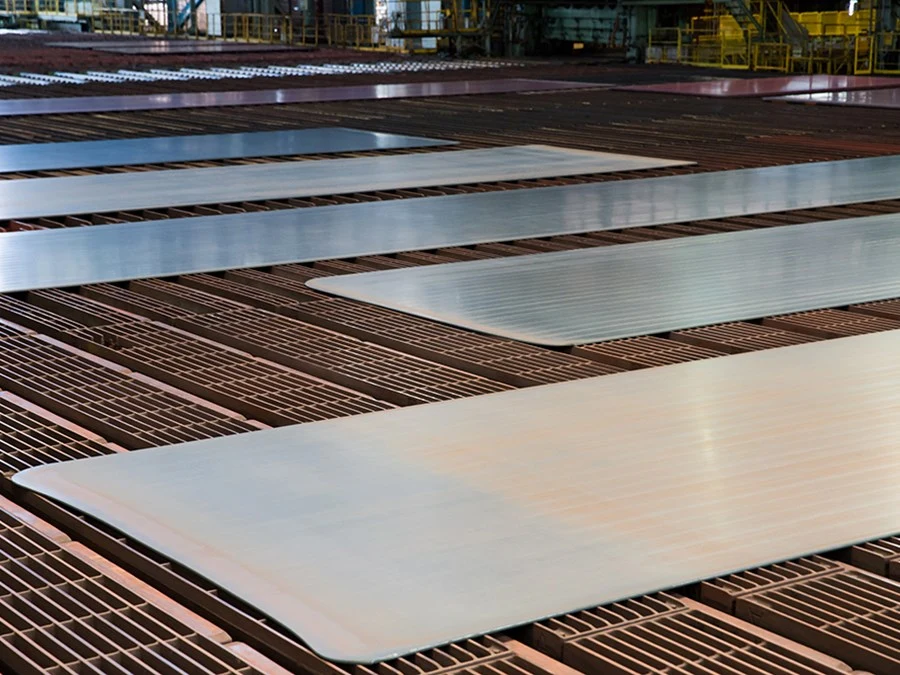

Recycled Steel

Material Profile & Sustainability

Steel is among the most recycled materials worldwide. Recycled steel can be melted and formed without degrading its structural properties. Using scrap steel reduces demand for virgin iron ore mining and significantly lowers energy consumption.

Modern production with electric arc furnaces (EAF) further reduces emissions when powered by renewables.

Benefits & Technical Strengths

-

Structural reliability: Same strength as virgin steel, suitable for beams, columns, trusses.

-

Durability: Resistant to termites, mold, and fire.

-

Prefabrication: Offers precision and reduced on-site waste.

-

Ash and waste reduction: Uses recycled content, reducing landfill burden.

Real-World Product Example

Product: ArcelorMittal XCarb™ Recycled Steel Beams

These beams are manufactured with high recycled content; the product line includes I-beams, H-beams, plates, and sections. They often come with traceable sustainability documentation, carbon savings metrics, and structural performance data.

Use Cases & Problem-Solving

-

Structural frames for multi-story or modular homes

-

Reinforcements for concrete slabs or shear walls

-

Roofing purlins, floor joists, and secondary supports

-

Quick-assembly prefabricated steel homes

Recycled steel addresses problems of resource depletion, energy-intensive virgin steel production, and construction waste. It allows builders to maintain strength while lowering carbon footprint.

How to Buy & Where to Buy

To purchase recycled steel structural members, approach steel distributors or manufacturers with green credentials. Use terms like “recycled structural steel beams.” Request environmental product declarations (EPDs). Many suppliers allow direct ordering via B2B portals.

Order Recycled Steel Beams

Rammed Earth & Stabilized Earth

Technique & Material Behavior

Rammed earth involves compacting a damp soil mixture (clay, sand, gravel) in reusable formwork. Sometimes stabilizers like lime, cement, or gypsum are added to enhance strength. A related material, Alker, is an earth-based stabilized product using gypsum and lime.

Stabilized earth walls are dense, thermally massive, and naturally breathable.

Benefits & Technical Strengths

-

Excellent thermal mass: In hot climates, walls absorb heat by day and release it at night.

-

Low embodied energy: Minimal processing needed if using local soils.

-

Long lifespan: Properly built rammed earth walls last decades with minimal maintenance.

-

Natural aesthetic: Earth tones and textures require little finishing.

Real-World Product Example

Product: Ecoliv Stabilized Rammed Earth Panels

These panels are factory-formed stabilized earth blocks or wall elements, with pigments, strength rating, and installation guidance. They often come with compressive strength ratings, weather performance, and handling specs.

Use Cases & Problem-Solving

-

Exterior walls in passive solar designs

-

Thermal buffer walls for desert or arid climates

-

Feature walls or structural walls in low- to mid-rise homes

-

Acoustic barriers in dense urban settings

Rammed earth solves overheating, reduces reliance on active HVAC, and cuts need for synthetic finishes. Stabilized earth like Alker allows structural performance beyond pure earth methods.

How to Buy & Where to Buy

To buy sustainable building materials like stabilized earth panels, contact natural building firms, earth construction specialists, or green building material suppliers. Ask for compressive strength, weather testing, and maintenance requirements. Some companies ship panels ready for stacking.

Buy Rammed Earth Panels

Cork

Material & Harvesting

Cork is harvested from the bark of cork oak trees every 9–12 years, without harming the tree itself. The trees continue to live and absorb CO₂, making cork a renewable, carbon-storing material.

Benefits & Advantages

-

Thermal and acoustic insulation: Very good R-values and sound absorption.

-

Lightweight & flexible: Easy to install as floor panels, wall tiles, or acoustic boards.

-

Natural fire retardant: Self-extinguishing and low-smoke emissions.

-

Moisture resilience & durability: Resistant to mold and water; long life.

-

Biodegradable & recyclable: At end-of-life, it can return to nature or be reused.

Real-World Product Example

Product: Amorim Cork Flooring Panels

These are high-density cork panels, often with protective coatings, and have documented thermal and acoustic performance. They come in various thicknesses and finishes.

Use Cases & Problem-Solving

-

Flooring for living rooms, bedrooms, and studios

-

Wall panels for noise control (home theaters, studios)

-

Ceiling panels for acoustic damping

-

Underlayment beneath other flooring materials

Cork addresses noise intrusion, thermal energy loss, and indoor humidity without heavy synthetic materials.

How to Buy & Where to Buy

To acquire high-quality cork panels or flooring, approach reputable cork manufacturers like Amorim or regional suppliers of natural building materials. Request technical data (thermal, acoustic, density) and ensure FSC or sustainability certification. Many sellers provide online ordering and sample kits.

Order Cork Panels

Reclaimed & Salvaged Wood

Definition & Environmental Value

Reclaimed wood is wood salvaged from old structures, barns, ships, or deconstructed buildings. Rather than being discarded, it is re-milled and reused avoiding new logging and reducing waste.

Benefits & Unique Advantages

-

Distinctive aesthetics: Weathered textures, patinas, and aging give character.

-

Structural robustness: Many reclaimed woods are from old-growth species with denser rings.

-

Low embodied energy: Minimal processing compared to fresh kiln-dried timber.

-

Carbon locked: The carbon sequestered from the original growth remains stored.

Real-World Product Example

Product: Elmwood Reclaimed Timber Flooring

These flooring planks or beams come with finishing options, moisture tolerance specs, and installation instructions. They often include remill warranties and provenance documentation.

Use Cases & Problem-Solving

-

Interior flooring with rustic or warm ambiance

-

Exposed ceiling beams or structural accents

-

Accent wall cladding

-

Custom furniture or millwork

Reclaimed wood addresses deforestation, landfill waste, and the demand for fresh timber. It gives design flexibility and environmental integrity.

How to Buy & Where to Buy

To buy sustainable building materials such as reclaimed wood, seek salvage yards, deconstruction suppliers, or specialized reclaimed wood companies. Ask for origin, moisture content, re-milling documentation, and finish compatibility. Many firms ship finished planks or beams ready for installation.

Buy Reclaimed Wood Flooring

Recycled Glass Concrete & Glass-Infill Aggregates

Material Concept & Sustainability

In recycled glass concrete, crushed, post-consumer glass replaces natural aggregates like sand and gravel. This reduces demand on virgin aggregate mining, reduces landfill glass, and gives a distinctive aesthetic sparkle. Some formulations also reabsorb CO₂ or reduce cement content.

Benefits & Performance

-

Lower embodied impact: Uses waste glass instead of virgin aggregate

-

Visual appeal: Offers translucent or glittering corridors in surfaces

-

Good compressive strength: Often comparable to standard concrete (depending on mix)

-

Recyclable at end-of-life: Can be crushed and reused

Real-World Product Example

Product: Vetrazzo Recycled Glass Panels/Countertops

Vetrazzo uses 85 % recycled glass in cementitious or polymer binders. These panels are used in countertops, flooring, walls, and façades, offering LEED credit potential.

Use Cases & Problem-Solving

-

Kitchen countertops or sink surrounds

-

Feature wall panels or cladding

-

Floor tiles with decorative translucence

-

Pavement infill or decorative aggregate surfaces

This material solves the twin problems of glass landfill waste and aggregate depletion, while also giving architects creative expression.

How to Buy & Where to Buy

To acquire recycled glass concrete panels or slabs, contact manufacturers like Vetrazzo or green stone fabricators. Request load-bearing specs, finish options, and shipping details. Many sellers allow custom sizing and online ordering.

Buy Recycled Glass Panels

Technology & Innovation in Sustainable Materials

Beyond the classic materials above, emerging technologies push the frontier further:

-

Transparent wood composites: Scientists have developed wood modified to have transparent optical properties, blending strength and light transmission.

-

Mycelium and fungal architecture: Researchers are exploring self-growing, self-healing fungal composites for future structures.

-

Bio-based aerogels from bacterial cellulose: Ultra-thin insulation films made from bacterial cellulose offer extremely low thermal conductivity for envelopes.

-

Earth 3D printing: Structures like the TECLA house use local clay mixes and 3D printers for low-waste, site-specific buildings.

These innovations, while still emerging, hint at a future where buildings self-adapt, repair, and require minimal external resource input.

Comparative Summary of Benefits

-

Carbon impact: Hempcrete can act as a carbon sink; bamboo captures CO₂; recycled steel avoids mining emissions; glass concrete repurposes waste glass.

-

Thermal & acoustic performance: Hempcrete and cork offer excellent insulation; rammed earth provides thermal buffering; glass concrete and bamboo add design aesthetic.

-

Durability & lifespan: Recycled steel and stabilized earth perform with long life; bamboo when treated can last decades; reclaimed wood and cork are robust with maintenance.

-

Health & indoor environment: Hempcrete and cork are breathable and non-toxic; bamboo and reclaimed wood reduce synthetic materials indoors.

How to Buy & Integrate into Projects

-

Set your performance targets (e.g. U-value, R-value, compressive strength) before selecting.

-

Locate regional suppliers of green or sustainable building materials—local sourcing reduces carbon and cost.

-

Request certifications and test reports (FSC, EPD, structural or thermal data).

-

Order sample units or small quantities to test finishes, handling, and compatibility.

-

Negotiate freight or delivery bulk discounts, especially for heavy materials.

-

Contractor education: Ensure your builders understand installation practices for these non-traditional materials (e.g. protective overhangs for hempcrete, moisture details for rammed earth).

-

Online platforms: Many specialized green building suppliers, marketplaces, or manufacturer websites offer direct ordering or dealer locator tools.

Frequently Asked Questions

Q1: Can sustainable materials match conventional strength and durability?

Yes. Recycled steel meets modern structural requirements, stabilized rammed earth and treated bamboo provide many decades of performance, and hempcrete infill is adequate when paired with structural frames.

Q2: Are these materials more expensive upfront?

Sometimes. Initial cost premiums may occur due to smaller scale or specialty processing. However, energy savings, maintenance reduction, and longer lifespan often yield lower total cost over decades.

Q3: Can I retrofit an existing house using these materials?

Absolutely. For example: cork panels can be overlaid on flooring; hempcrete or cork insulation can be added into cavity walls; reclaimed wood can replace finishes; recycled glass surfaces can reface countertops.