Best Sustainable Materials for Building Houses – Eco‑Friendly Construction Guide

Why Sustainable Building Materials Matter

Green or sustainable building materials help reduce environmental impact across the entire lifecycle of a home from extraction, manufacturing, transport, use, maintenance, to end‑of‑life disposal or reuse. They reduce carbon emissions, waste, pollution, and are often healthier for occupants (fewer off‑gassing chemicals). Over time, they often lower operational costs (energy, maintenance) and can improve durability and resilience to climate stresses.

Using sustainable materials also aligns well with green building standards (e.g. LEED, BREEAM, Green Star), helps improve resale value, and draws interest from eco‑conscious buyers. For someone ready to build or renovate, specifying sustainable materials is a way to convert a home into a more future‑proof, efficient, and environmentally responsible asset.

Leading Sustainable Materials for Houses

Below are several of the most promising sustainable materials. Each has unique strengths, challenges, and ideal use cases.

Bamboo / Engineered Bamboo

Bamboo is a fast‑growing resource (harvestable in 3–5 years) and is renewable. Engineered bamboo (e.g. laminated bamboo panels or bamboo scrimber) can approach the strength of hardwood and is increasingly used in structural, flooring, and façade elements.

In use, bamboo’s flexibility and tensile strength make it suitable for earthquake zones or lightweight construction. It can be applied as cladding, flooring, structural members (in low to medium load zones), and decorative finishes. Because bamboo sequesters carbon during growth, it offers a favorable carbon footprint compared to conventional timber.

Use case & problem solved: In locations where hardwood is expensive or ecologically sensitive (tropical forest regions), bamboo offers a sustainable local alternative with good structural potential. For modular housing, engineered bamboo panels can reduce weight while maintaining stiffness and strength.

Considerations: Bamboo must be treated against pests and moisture. In high humidity or ground contact, protective coatings or raised bases are needed. Quality control is essential to avoid weak or inconsistent culms.

Hempcrete

Hempcrete (a mixture of hemp hurds, lime binder, and water) is an insulating, breathable biocomposite used as wall infill or insulation. It is lightweight, low‑energy to produce, and can act as a carbon sink (the hemp plant absorbs CO₂ as it grows).

It is not load-bearing (so it must be used in conjunction with a structural frame), but offers excellent thermal and acoustic insulation, humidity regulation, and resistance to mold.

Use case & problem solved: In a climate with large temperature swings or moisture challenges, hempcrete walls help maintain indoor comfort without needing heavy mechanical systems. It helps solve insulation or condensation issues in older homes by offering a breathable, vapor‑regulating layer.

Considerations: Hempcrete is still relatively niche, with limited suppliers in many regions. It also requires careful detailing to avoid structural load issues and to integrate with conventional framing.

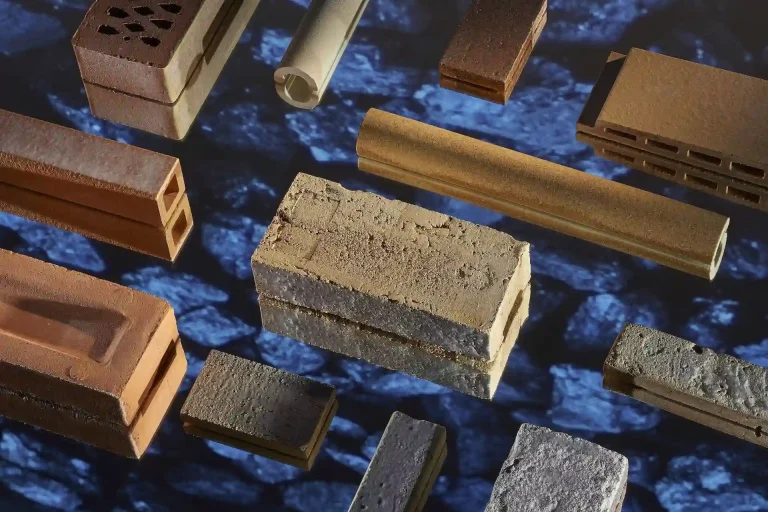

Rammed Earth / Compressed Earth Blocks

Using locally sourced soil (stabilized with small amounts of cement, lime or other additives), rammed earth or compressed earth blocks (CEBs) create durable walls with high thermal mass. These walls can absorb heat during the day and release it at night, smoothing indoor temperature swings.

Because the raw materials often come from on‑site excavation or nearby, transport emissions and embodied energy drop significantly. The visual finish (layered earth tones) is often architecturally appealing.

Use case & problem solved: In dry or semi-arid climates, rammed earth walls reduce reliance on heating/cooling systems. For owners with on‑site soil, it reduces material import costs and integrates well with passive solar designs.

Considerations: Earth construction is more sensitive to moisture, so proper waterproofing, drainage, and roof overhangs are essential. Structural reinforcement must be considered, especially in seismic zones.

Recycled Steel

Steel is among the most recycled building materials globally. Using recycled steel for structural beams, rebar, or framing reduces demand for virgin steel, cutting energy and CO₂ emissions.

Because steel is strong, dimensionally precise, and non‑combustible, it fits well with modern modular and prefabricated designs. It is also resistant to termites and pests (important in many tropical regions).

Use case & problem solved: For large spans, open floor plans, or prefabricated structures, recycled steel lends strength with less material mass. It solves the structural demand for high load zones while keeping carbon footprint lower than virgin steel.

Considerations: Steel is thermally conductive (risk of thermal bridging), so proper insulation and thermal breaks are essential. Corrosion protection must be applied in damp or coastal settings.

Cork

Cork, harvested from cork oak bark (without cutting down the tree), regenerates every 9–12 years. It offers natural thermal and acoustic insulation, light fire resistance, moisture resilience, and low environmental impact.

Cork is commonly used for insulation boards, wall coverings, flooring underlayment, and sound‑absorbing panels. Its elasticity and durability make it ideal in flooring and interior finishes.

Use case & problem solved: In homes seeking noise control (e.g. adjacent to busy roads) or improved insulation, cork panels serve dual roles. As a flooring underlayment, it reduces cold, damp floors while improving acoustic comfort.

Considerations: Cork supply is regionally limited (mostly in Mediterranean regions). Quality and density must match required insulating performance. It is less suited for structural elements.

Other Emerging & Experimental Materials

-

Mycelium (fungal root networks) can be grown into lightweight, biodegradable insulation panels or formworks.

-

Recycled plastic / composite materials: Turning PET bottles or waste plastic into building blocks, panels or insulation helps close the waste loop.

-

Biochar concrete / “green concrete” blends: Adding carbon‑rich biochar or using waste materials in concrete mixes reduces embodied carbon while boosting strength or durability.

-

Transparent wood: Removing lignin and replacing it with polymers can make strong, translucent wood that functions like glass while offering better insulation.

These experimental materials are still scaling, but they point toward a more diverse, low‑carbon future.

Real‑World Products & Examples

Below are five real products (or systems) that embody sustainable building materials, with practical details, benefits, use cases, and how you could source them. (These are illustrative availability may vary by region.)

1. Bamboo Ply / Laminated Bamboo Panels

These are engineered bamboo boards or panels made by gluing and compressing bamboo strips in multiple directions, creating boards usable like plywood or laminated timber.

Benefits:

-

High strength-to-weight ratio

-

Renewable and fast-growing

-

Reduced carbon footprint compared to traditional hardwood

-

Aesthetic warmth and natural grain

Use case: Use these panels for interior walls, cabinetry, cladding, or even floor structures in light loads. In tropical climates, bamboo ply is ideal due to its moisture stability when properly treated.

Where to buy / how to get them: Buy Laminated Bamboo Panels

2. IsoHemp Hempcrete Blocks

IsoHemp is a known brand in Europe producing hempcrete blocks, lime–hemp plasters, and insulation materials for sustainable construction.

Benefits:

-

Excellent insulation and thermal regulation

-

Breathability and mold resistance

-

Carbon capture during hemp growth

-

Lightweight and easy to handle

Use case: Use IsoHemp blocks for internal or external wall infill (with structural support), or hemp lime plaster as finishing. In retrofit projects, hempcrete helps replace conventional insulation while improving indoor air quality.

Where to buy / how to get them: Buy IsoHemp Hempcrete Blocks

3. Amorim Cork Insulation Boards

Cork insulation boards produced by brands such as Amorim CorkTech are made from sustainable cork bark compressed into panels.

Benefits:

-

Natural thermal and acoustic insulation

-

Vapor permeability (breathability)

-

Non-toxic, recyclable

-

Fire-resistant to certain grades

Use case: Use cork boards for wall insulation, under screeds, sound barriers between floors, or interior wall linings for improved acoustic comfort.

Where to buy / how to get them: Buy Amorim Cork Insulation Boards

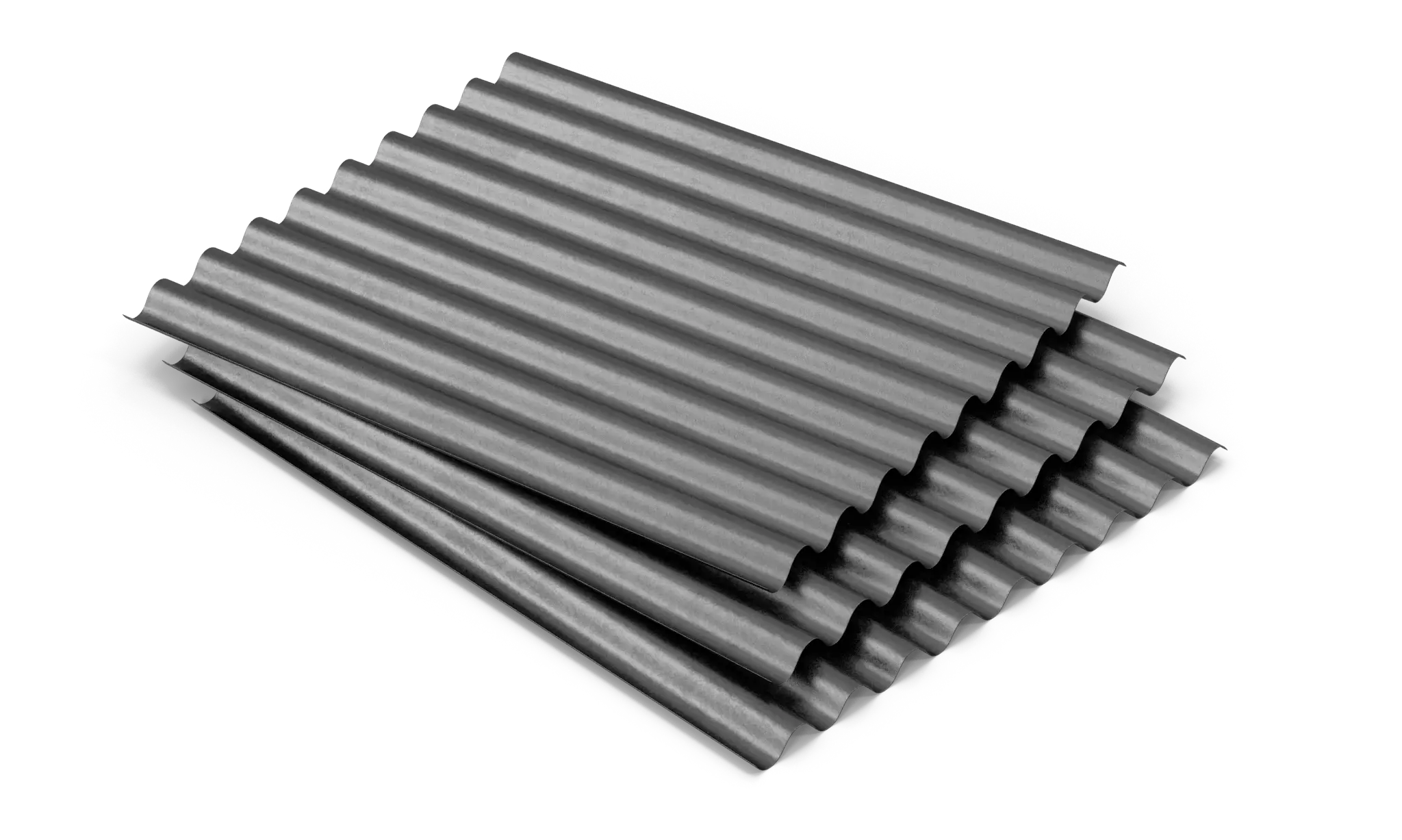

4. BlueScope Z Grade Steel

BlueScope (in Australia) offers steel products that include a high proportion of recycled content, used in framing, roofing, cladding, and structural sections.

Benefits:

-

High strength and reliability

-

Recyclability at end-of-life

-

Lower carbon footprint than virgin steel

-

Non-combustible

Use case: Use recycled steel beams, purlins, and studs in framing, roof structures, and industrial or modular home systems. Suitable for long spans or hybrid designs.

Where to buy / how to get them: Buy BlueScope Z Grade Steel

5. Rammed Earth Building Blocks

Alker is a stabilized earth block system mixing earth, gypsum, lime, and water. It can be molded in blocks or cast in-situ (rammed earth).

Benefits:

-

Low embodied carbon (using local earth)

-

High thermal mass and energy performance

-

Natural aesthetic, durable walls

-

Lower transport emissions

Use case: Use Alker blocks for load-bearing and non-load-bearing walls in houses where soil conditions are favorable. It’s especially effective in climates where diurnal temperature swings are significant, helping stabilize interior temperature.

Where to buy / how to get them: Buy Rammed Earth Building Blocks

Advantages & Benefits of Using Specific Sustainable Materials

Below we dive deeper into benefits and how each material helps solve common building challenges.

Lower Embodied Energy & Carbon

Many sustainable materials require less energy to extract, process, or transport compared to conventional concrete, steel, or fired bricks. For example, hempcrete and rammed earth use local, low‑processing inputs, reducing emissions. Bamboo sequesters carbon while growing. Recycled steel avoids the energy of smelting virgin ore.

By lowering embodied carbon, your home’s “carbon budget” over its lifetime is reduced, aligning with low carbon / net zero goals.

Improved Thermal & Acoustic Performance

Materials like hempcrete, cork, rammed earth, and engineered bamboo offer natural insulation or thermal mass. Hempcrete moderates indoor temperatures and reduces heating/cooling loads. Cork reduces sound transmission. These performance gains mean smaller HVAC systems, lower energy bills, and better occupant comfort.

Durability, Resilience & Health

Many sustainable materials resist pests, mold, decay, and offer vapor permeability. Hempcrete helps control humidity. Bamboo (when treated) is robust and flexible. Recycled steel resists termite damage. Materials with natural, low-VOC composition improve indoor air quality.

Cost & Lifecycle Savings

While some sustainable materials have higher upfront cost, the improved performance and lower maintenance often recoup investment over years. Energy savings, lower HVAC sizing, fewer replacements, and incentive rebates can improve return.

Aesthetic & Market Appeal

Natural textures, earth tones, wood-like finishes, or exposed earthen walls appeal to many homeowners and architectural styles. A sustainably built home can command premium resale value or attract eco-conscious buyers.

Use Cases: What Problems These Materials Solve

-

High energy cost climates – Hempcrete, cork, and rammed earth reduce heating/cooling demand.

-

Noise or acoustic control – Cork and hempcrete provide sound dampening in multi-unit homes or near traffic.

-

Tropical humidity and mold – Breathable materials like hempcrete, cork, and rammed earth help regulate humidity and prevent mold.

-

Limited local timber supply – Bamboo or engineered bamboo provide alternative to expensive imported wood.

-

Low-carbon / net-zero goals – Recycled steel, biochar concrete, hempcrete all help reduce carbon footprint.

-

Natural aesthetic or biophilic design – Earth walls, bamboo finishes, cork textures provide connection to nature.

People need these materials because future regulations, carbon constraints, resilience against climate change, and healthier indoor environments are increasingly essential.

How to Buy & Where to Source

-

Local green building suppliers: Many cities have niche suppliers of sustainable materials. Visit or search “eco building materials supplier” in your locale.

-

Manufacturer/distributor websites: Use product links or contact brands directly (e.g. IsoHemp, Teragren, Amorim) to find local dealers or shipping options.

-

Trade shows / expos / green building fairs: These events often bring together sustainable product vendors and allow you to inspect physical samples.

-

Online marketplaces: Some eco‑materials are sold on platforms like Alibaba, regional B2B sites, or specialized green building e‑commerce sites.

-

Architects / sustainable builders: Engage professionals who already work with these materials they may have sourcing channels or bulk discounts.

Always check shipping cost, local import rules, and material compatibility with local climate and building codes.

Implementation Tips & Best Practices

-

Start early in design phase: Sustainable materials demand careful detailing (moisture control, structural integration, interfaces with conventional materials).

-

Test small samples: Order small panels or blocks to test performance (e.g. moisture, strength, appearance) before full use.

-

Pay attention to compatibility: Use proper adhesives, sealants, finishes compatible with breathable or natural materials.

-

Detail for moisture control: Especially for earth-based or bio‑materials, ensure good drainage, overhangs, vapor control layers, and capillarity barriers.

-

Coordinate with structure: Many sustainable materials are non-load bearing. Use structural frames (e.g. bamboo, steel, timber) and infill with sustainable elements.

-

Local adaptation: Climate, humidity, seismic risk, local soil, and material supply vary adapt your choice to the local context.

Summary

Choosing sustainable materials for building houses is not just an environmental statement it’s a smart, long-term investment in performance, health, resilience, and cost efficiency. Whether you opt for bamboo, hempcrete, rammed earth, recycled steel, cork, or even experimental materials like mycelium, the key is aligning the material’s strengths with your climate, design, budget, and regulatory environment.

By understanding the benefits, use cases, product options, and sourcing strategies outlined above, you’ll be better positioned to create a home that’s beautiful, efficient, low impact, and future-ready.

Frequently Asked Questions

Q1: Are sustainable building materials always more expensive upfront?

A: Not always. Some sustainable materials (e.g. rammed earth using on-site soil) can reduce transport and raw material costs. Others may have a premium due to limited supply or novelty. However, lifecycle savings (energy, maintenance, reduced replacements) often offset the initial higher cost.

Q2: Can I mix sustainable materials with conventional materials (concrete, steel)?

A: Yes hybrid systems are very common. For instance, use a steel or timber structural frame and infill with hempcrete or rammed earth, or use bamboo cladding over conventional structure. The key is correct interface detailing.

Q3: How do I ensure these materials meet building codes and standards?

A: Work with architects or engineers familiar with green building, validate materials with test data (mechanical, fire, moisture), check local building code allowances, and use certified or tested products whenever possible.